FRP Installation

FRP glue plus FRP panels and an experienced team equals a clean project you can enjoy for years without any fuss. After installation on walls or ceilings, FRP is maintenance-free, besides the cleaning...which is the primary reason for most installations anyway.

What is FRP?

Fiberglass reinforced panels (FRP) are most often used in environments where frequent cleaning takes place. The thin plastic is very difficult to scratch and greatly versatile when it comes to washing. They are lightweight and flexible especially compared to drywall. Many times the installation is requested or expected due to sanitation purposes called for by the use of the room. By using these panels in your kitchen or food processing facilities, restrooms, pet areas, children's areas, or hospital and medical spaces, you're doing yourself or your staff a favor because the clean up work will be greatly decreased. A bucket and mop, a hose, or even a soaking wet, soapy sponge can be taken to FRP panels without concern. They are even advertised to hold up against pressure washing and steam. The primary purpose while accepting any level of moisture, light chemicals, and constant cleaning, is that FRP is designed to prevent anything from getting behind it. Commonly seen in gas stations, day care or school buildings, and sometimes in hotels, restaurants, commercial retail outlets, fitness, gym or recreation spaces we'll do an excellent job of installing FRP in Tampa or nearby cities. Whether it's a cafeteria in Lutz, or a fast food chain in Brandon, or a refrigerated warehouse near Ybor and the Port of Tampa, we can install FRP into almost any space with walls.

They will also not rust, scratch, peel, or dent under normal conditions. Its properties allow for it to avoid corrosion and resist moisture and mold even in highly humid environments. Fiber-reinforced plastic (FRP) is commonly used in facilities that have USDA and FDA inspections. Because of their ease of cleaning and inspection, they are popular in these settings for sanitary purposes as well as around baths or indoor pools for protection against moisture. This plastic should not develop mold or mildew which are prone to appearing over time on other materials that are installed around wet areas. We have great reputations with general contractors for work we have performed beyond FRP specialties, such as drywall and stucco. In need of multiple services, call and ask. We offer some great turnkey options because out team is skilled beyond just one trade.

Installing Fiberglass Reinforced Plastic

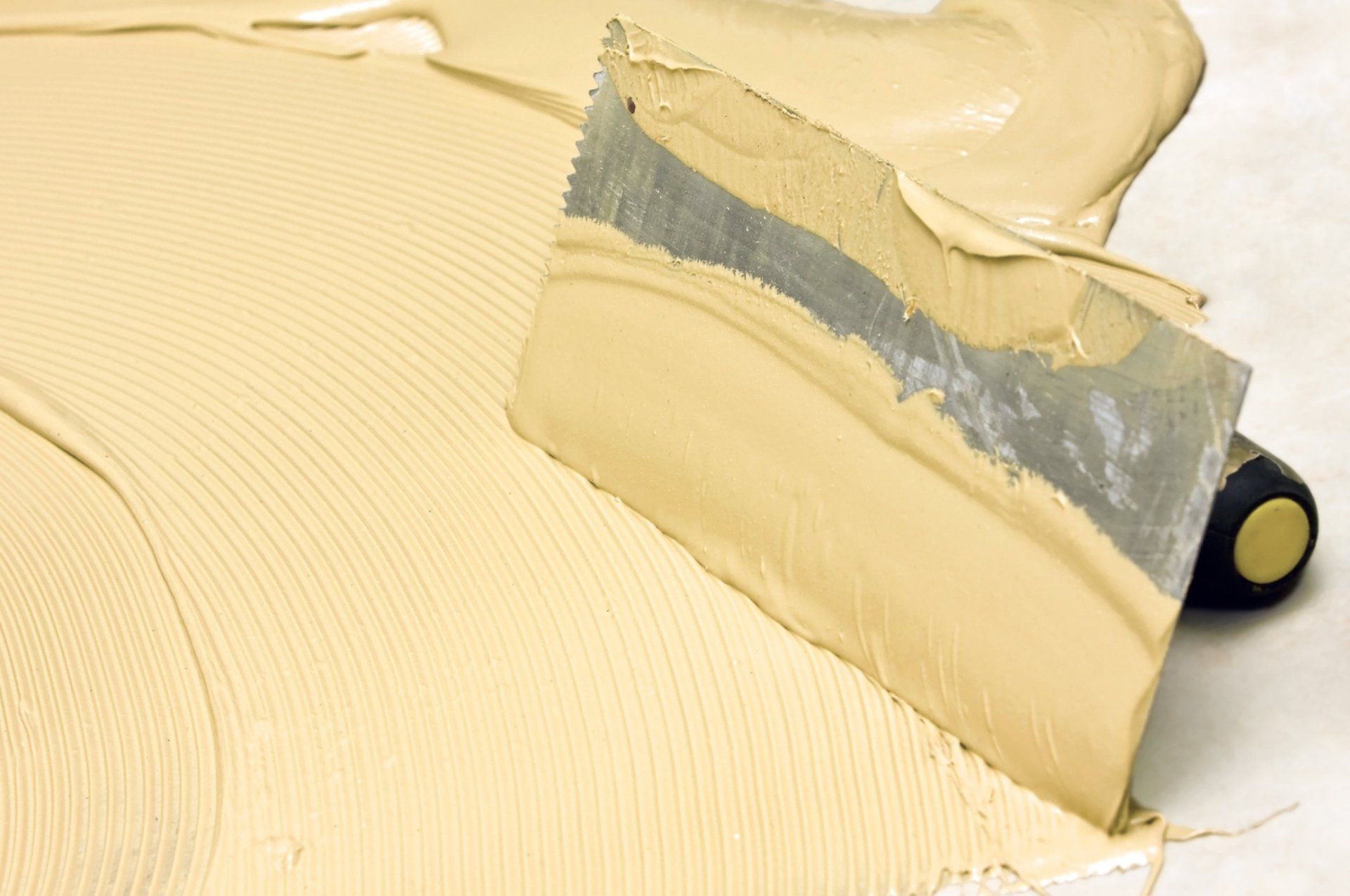

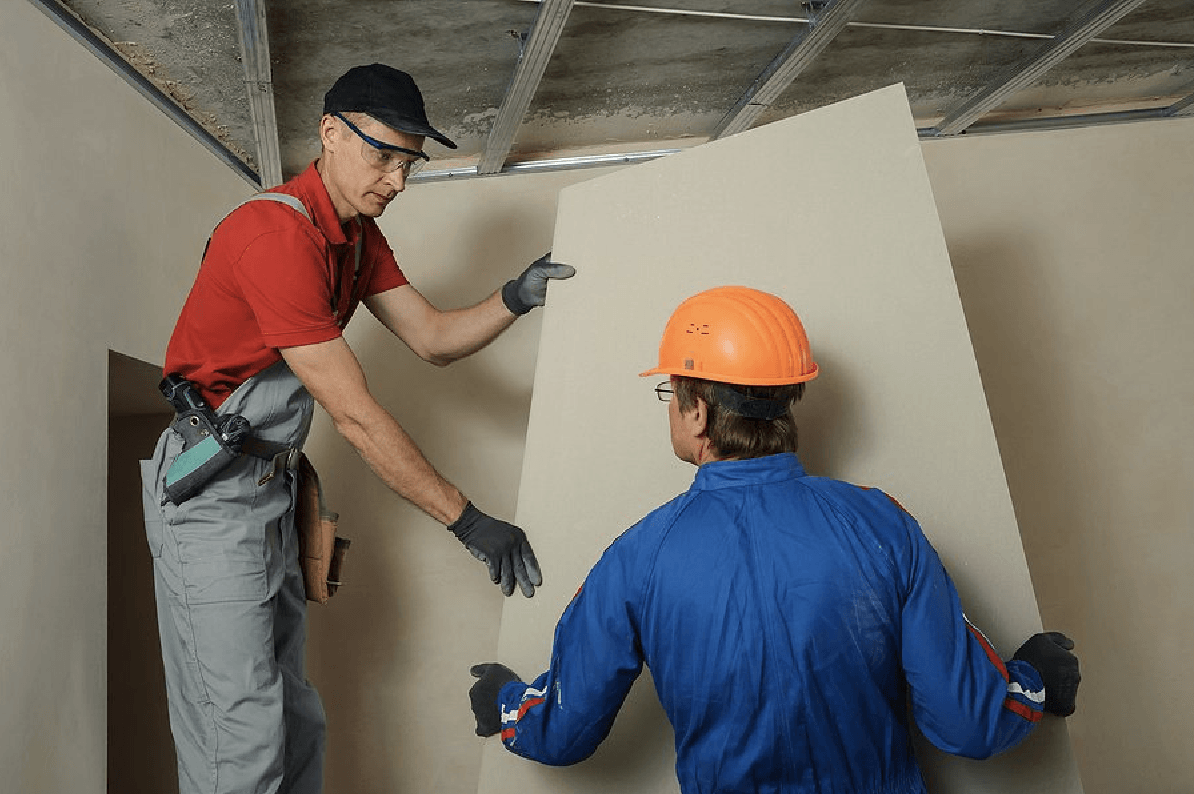

We can install these over old or new drywall, concrete, block, wood, tile, and so many other surfaces. We'll gladly examine your walls to determine if any additional work needs to happen before the panels can be applied. The walls need to be completely dry before installation because FRP is a non-breathable material. Sometimes more glue and a little extra work may be required for certain surfaces, but nearly any type of strong wall can be used as the backdrop. There is more than one type of glue, so we'll determine what option is best for your wall. With the ability to be applied over walls of nearly any condition, fiberglass reinforcement plastic can be a cost effective option due to the lack of prep work involved. However, the surface needs to be smooth so we'll remove any uneven areas ahead of the installation in order to ensure proper adhesion.

FRP Fasteners

Occasionally plastic rivets or mechanical fasteners are required for the best installation and security. We'll review your site, the condition of the existing walls, as well as what the purpose is of any given rooms in order to determine the best combination. In most cases adhesive is sufficient but we must ensure complete coverage of the adhesive in between all panels and the wall. When dealing with glue, anything less than 100% coverage could result in air pockets. Water based adhesive is most commonly used but there are exceptions such as if we need to install over cinder block or tile that is not perfectly smooth.

We follow best practices by applying a silicone sealant or caulk around all edges and along the seams or joints. If any type of rivet is installed, the same sealant should be applied for maximum protection against any substance getting behind the FRP paneling.

FRP Molding

This type of molding is specifically designed to receive FRP sheets. There are inside corner molds, outside corner molds, division bars, baseboard molding, and top caps. Each variation is used on a different end or joint in order to further prevent any wetness or substance from penetrating the FRP and potentially getting behind it. As stated above, most mold edges will be finished with sealant. The panels is never firmly inserted into the molds during installation rather a little wiggle room is always left. What this does is allow for the sheets to expand and contract without causing adverse effects to the installed wall panels.

While the product is relatively inexpensive and has a simple function, it is very common and amazingly effective. If you have an area that requires or could benefit from FRP, let us take a look and discuss the project with you.

Please also be aware that we have added a new material to our portfolio: installation of pvc wall panels. These are similar to FRP but may not meet the stringent standards in agriculture or food prep areas that FRP offers. PVC can go up fast and has many of the same advantages that FRP offers. You can check out our dedicated

pvc panel page to read more about specific properties and advantages of using pvc.

Can FRP be painted?

Yes, FRP can be painted. However there are some additional factors you should consider before painting FRP in your business.

For best adherance, sand the surface before you apply a paint or primer. This will help the paint stick to the sheets and last longer.

For new installs, it is a much better option to search for the panels in a color closest to what you need. We can source FRP in different colors so ask us about that if your company wants that.

If you're going to paint the panels on your wall, we suggest using an epoxy-based paint. Unlike drywall which is matte and more absorbant, FRP is water resistant so it is not designed to hold paint well. A cheap paint may not remain for as long as you'd like because of the properties of fiber reinforced plastic. You can imagine how your building will look if the paint is easily chipping or peeling off the walls. And if you're in a sanitary location, the paint that comes off could pose an issue if it is frequent.

Lastly, keep in mind how often you will be cleaning the surface and what your employees will be using to do so. A strong cleaning agent, harsh brush or strong water jet could take the paint off over time. FRP comes in a gloss finish which is designed for easy cleaning so if you're constantly working on the product, your paint may start to loose its adherance quicker than normal.

If your FRP panels are in a lower traffic area or none of the above situations pose major problems to your facility, it is safe to paint your FRP. It should not ruin or damage the product if you choose to do so.

Can FRP be used on ceilings?

Yes, FRP can be installed as both wall and ceiling panels.

Often times, the goal of installing FRP panels on a ceiling is for easier maintenance. With less seams, cleaning becomes easier which saves your team money in the long run. Smooth, less porous versions of FRP are available when sanitation is the number one concern for your walls and ceilings.

When dealing with a massive food prep area or a food processing plant on the scale of a warehouse, installation is also a factor. FRP panels are easy to install into ceiling grids which can save you time and money during a new build or a retrofit.